In industrial production and logistics transportation, casters are indispensable components. However, traditional casters often generate noise during operation, which affects the working environment and the lifespan of the equipment. With the increasing demand for quietness in industrial equipment, quiet casters have gradually become the focus of the industry. So, how is the noise reduction of casters achieved? This article will reveal it to you from three aspects: materials, structure and process.

I、Daisui Quiet Foot Wheels

1. Material Selection: The Foundation of Noise Reduction

The noise produced by the casters mainly comes from the friction between the wheels and the ground, as well as the rotation of the bearings. Therefore, the choice of materials is of utmost importance.

Wheel material: Polyurethane (PU), rubber and TPE and other elastic materials have become the preferred choice for noise-reducing casters due to their excellent shock absorption and low noise characteristics. For instance, the DS98 series of Daishi casters use polyurethane wheels. Not only are they wear-resistant, but they can also effectively absorb vibrations and reduce noise. In addition, Daishi has also launched several TPE casters. These casters are made of high-performance TPE materials and possess excellent wear resistance, elasticity and low noise performance, which are suitable for medical equipment, furniture and logistics handling and other fields.

2. Bearing material: High-quality ball bearings can reduce the frictional noise during rotation. The large-world casters are equipped with ball bearings to ensure smooth and quiet operation.

3. Surface treatment: The eco-friendly galvanizing and electrophoretic coating processes not only prevent rust but also reduce the frictional noise between metal components.

II、Structural Design: The Core of Noise Reduction

The structural design of the casters directly affects their noise reduction effect.

1.Shock absorption structure: The DS98 series of Daishi wheels adopt a high-performance rubber block shock absorption design. By absorbing vibration energy, it significantly reduces noise.

2. Double-layer steel ball track: This design enhances the load-bearing capacity of the casters while reducing the friction noise during rotation. For instance, the DS50 series casters adopt a double steel ball track, ensuring smooth operation and quietness.

3. Connection method between the wheels and the supports: A fully welded structure and double-sided welding process are adopted to reduce the noise caused by loose components.

III、Production process: Assurance of noise reduction

Advanced production techniques are the key guarantee for reducing the noise of the casters.

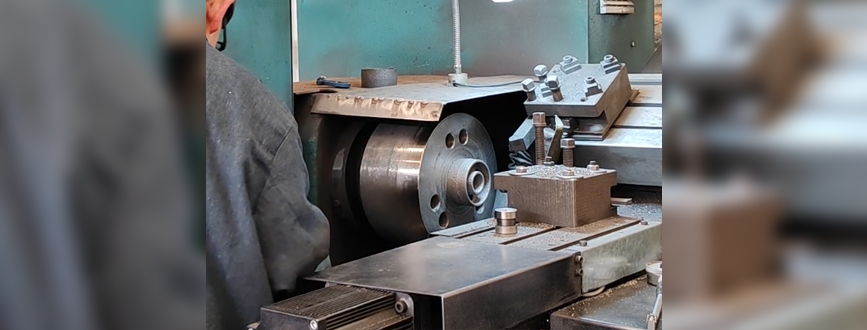

1.Precision processing: The large-world wheels are manufactured using an automatic casting assembly line and computerized precise pre-forming machines, ensuring the accuracy of each component and reducing noise caused by size errors.

2. Heat treatment process: The base plate and the steel ball disc are subjected to heat treatment to enhance their strength and wear resistance, thereby reducing the noise generated during long-term use.

3. Customized production: The color, size and installation method of the wheels can be customized according to customer requirements to ensure a perfect fit between the casters and the equipment, thereby reducing noise caused by mismatches.

The noise reduction of the casters not only enhances the user experience of industrial equipment, but also extends the equipment's lifespan and reduces maintenance costs. Through continuous innovation in materials, structure and process, Daishi casters have provided a reliable solution for industrial quietness. In the future, with the advancement of technology, the noise reduction performance of casters will further improve, bringing more possibilities to the industrial field. If you are looking for a reliable caster solution, please contact Daishi Heavy Duty Casters. We will provide you with professional products and services!

This article is copyrighted by Dashi Gecun. Reproduction is prohibited without proper attribution:http://www.caster.cn