-

Advanced Engineering Team

With deep industry experience and technical expertise, our team tackles the complex challenges.

-

In-House Manufacturing & Testing

Our fully equipped facilities ensure precise and consistent results for every caster.

-

Full Lifecycle Control

From design to post-sale service, we manage the entire lifecycle in-house.

-

Global Export Compliance

Mastery in global trade, standards, and certifications.

From development to outbound delivery and after-sales service.

Gain a deep understanding of the customer's application scenarios, standards, and customization requirements.

DS Caster Advantage: One-on-one support from multilingual sales experts ensures rapid and accurate understanding of global market technological needs.

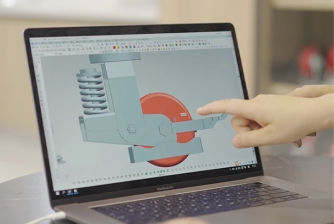

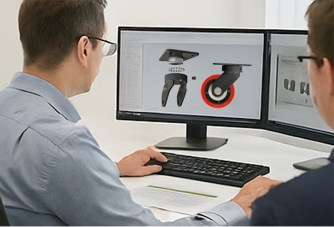

Dasign the structure based on operating conditions, and determine materials and

manufacturing processes.

DS Caster Advantage: Independent R&D capability with design customization based on European and American standards for high adaptability and reliability.

Provide detailed quotations along with 2D/3D drawings to support customer evaluation

DS Caster Advantage: Fast response, clear and professional drawings, and support for internal technical reviews on the customer side.

Produce samples based on design drawings to ensure functional and structural compliance.

DS Caster Advantage: Short lead times, flexible response, and rapid optimization based on feedback.

Verily process stability, ensure consisteney and delivery capability for batch production.

DS Caster Advantage: High-efficiency transitions from trial to mass praduction with stable production lines and process control system.

-

06.1 Stamping

Steel plate is stamped into key structural components quickly.

DS Caster Advantage: High speed stamping equipment, combined with independently developed molds, ensure efficient production and dimensional consistency.

-

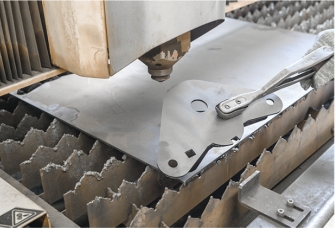

06.2 Laser Cutting

Precisely cut complex profiles and control hole and edge dimensions.

DS Caster Advantage: German-brand laser cutting equipment provides high precision cutting and smooth incision, and there is no need for secondary processing.

-

06.3 CNC Machining

Precision machining for contact surfaces, mounting holes, and critical dimensions

DS Caster Advantage: Multi-axis CNC machine tools imported from Japan ensure dimensional accuracy and perfect assembly compatibility.

-

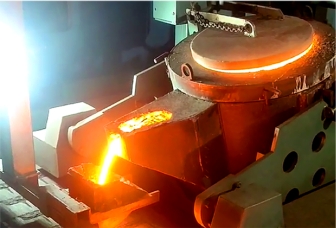

06.4 Heat Treatment

Enhance the strength, wear resistance, and deformation resistance of metal parts.

DS Caster Advantage: Long-term cooperation with leading Chinese heat treatment specialists, ensuring critical processes are precisely controlled.

-

06.5 Welding

Welding can firmly connect various structural components

DS Caster Advantage: Robotic welding combined with manual refinement ensure structural strength and clean weld appearance.

-

06.6 Surface Treatment

Adopting galvanization, electrophoresis, and powder coating etc anti-corrosion coating processes.

DS Caster Advantage: Multiple surface treatment options are suitable for different environments; durable and aesthetically pleasing surface treatment effect.

-

06.7 Assembly (Top Plate, Bearings, Dust Caps, Forks, etc.)

Assemble components into a complete bracket unit according to standard procedures.

DS Caster Advantage: Tool-assisted standardized assembly with manual inspection ensures consistency and reliability.

-

07.1 Casting

Wheel cores forming or metal support structures.

DS Caster Advantage: Precision molds ensure excellent strength and dimensional stability of the wheel cores.

-

07.2 Machining Process

Fine machining process for wheel cores, outer surfaces, and mounting holes.

DS Caster Advantage: CNC turning ensures low runout and smooth wheel rotation.

-

07.3 PU Pouring

Pouring polyurethane material onto the wheel core uniformly .

DS Caster Advantage: Proprietary formular ensures high elasticity, wear resistance, and adhesion suitable for various industrial floor conditions.

-

07.4 Automatic Injection Molding Line

Integrating the wheel surface and plastic core in one molding process

DS Caster Advantage: The fully automated injection molding production line provides high efficiency and consistent quality, suitable for large-scale high-quality production.

-

07.5 Bearing Assembly

Accurately install bearings into the wheel core.

DS Caster Advantage: Specialized assembly machines combined with manual inspection ensure smooth rotation and balanced load performance.

Integrate the bracket and wheel to ensure stable performance in rotation, braking, and load bearing.

DS Caster Advantage: Standardized procedures and manual inspection ensure assembly accuracy and overall wheel performance.

Provide protective, segmented, and labeled packaging as per customer requirements.

DS Caster Advantage: Flexible packaging solutions with customizable labels and stacking methods ensure safe transport and easy storage.

Manage finished product storage, warehousing records, and delivery management.

DS Caster Advantage: The intelligent warehousing management system and advanced first in first out (FIFO) control ensure shipping efficiency and inventory transparency.

Arrange shipments according to the customer's delivery schedule and handle customs clearance and logistics coordination.

DS Caster Advantage: Expert at international logistics and compliance, offering one-stop delivery service from factory to destination.

Technology-Backed Assurance for Every Project.

We invest in comprehensive testing and inspection tools to guarantee durability, safety performance. Our in-house labs simulate real-world working conditions to ensure your casters stand up to any challenge before they leave our factory.

-

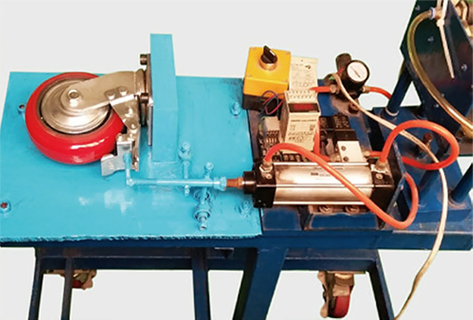

Brake Fatigue Test

Brake Fatigue Test -

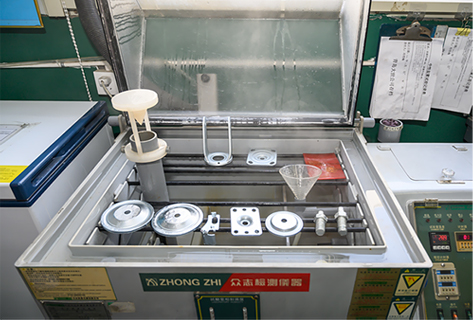

Salt Spray Test

Salt Spray Test -

Hardness Test

Hardness Test -

Load Test For Light Duty Caster

Load Test For Light Duty Caster -

lmpact & Resistance Test

lmpact & Resistance Test -

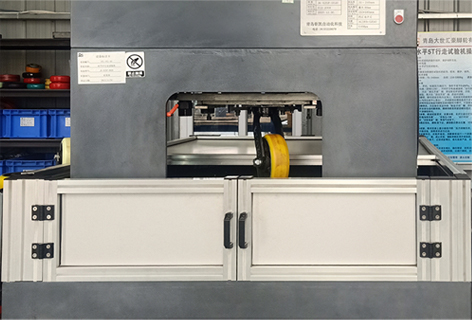

Load Test For Heavy Duty Caster

Load Test For Heavy Duty Caster

Eliminate Uncertainty

Get a Custom Solution that Works

Each solution is developed in close collaboration with your team,

ensuring every detail from materials to mounting systems is aligned with your goals.